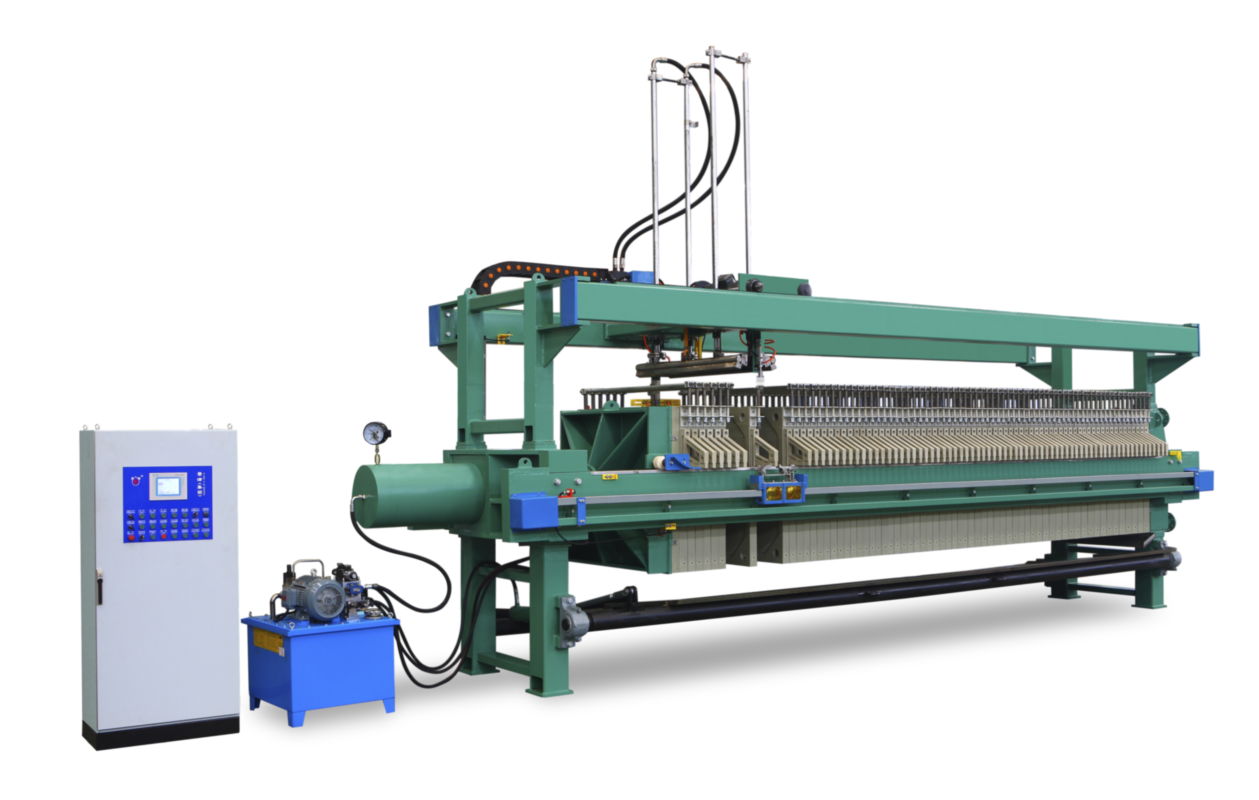

A small filter press is a type of filtration equipment that is used to separate solids and liquids. It works by using a series of filter plates and a hydraulic system to apply pressure to the slurry, forcing the liquid to pass through the filter cloth and leaving the solids behind. Small filter presses are typically used for smaller-scale applications, such as in laboratories, pilot plants, and small industrial operations.

The main components of a small filter press include the frame, the filter plates, the hydraulic system, and the filter cloth. The frame holds the filter plates in place, while the hydraulic system applies pressure to the slurry to force the liquid through the filter cloth. The filter plates are designed to hold the filter cloth in place and allow the liquid to pass through while retaining the solids.

Small filter presses can be used for a variety of applications, such as:

Separating solids from liquids: Small filter presses are commonly used to separate solids from liquids in applications such as wastewater treatment, chemical processing, and food and beverage production.

Testing and research: Small filter presses are often used in laboratories and pilot plants for testing and research purposes.

Small-scale industrial operations: Small filter presses can be used in small-scale industrial operations, such as in the production of specialty chemicals or pharmaceuticals.

Some benefits of using a small filter press include:

Efficient filtration: Small filter presses are designed to provide efficient filtration, with high-quality filter plates and filter cloths that can remove a high percentage of solids from the liquid.

Cost-effective: Small filter presses are small filter press often more cost-effective than larger-scale filtration equipment, making them a good option for smaller-scale operations or research projects.

Easy to use: Small filter presses are typically easy to operate, with simple controls and straightforward procedures.

Versatility: Small filter presses can be used for a variety of applications and can be customized to meet specific needs and requirements.

Overall, small filter presses are a reliable and cost-effective option for separating solids and liquids in a variety of applications.

How does the hydraulic system apply pressure to the slurry?

The hydraulic system in a filter press applies pressure to the slurry by using a hydraulic cylinder and a hydraulic pump. Here is a general overview of how the hydraulic system applies pressure to the slurry:

- The slurry is pumped into the filter press and distributed evenly among the chambers formed by the filter plates.

- The hydraulic pump is activated, which pumps hydraulic fluid into the hydraulic cylinder.

- The hydraulic cylinder is connected to the filter press frame, and as the hydraulic fluid is pumped in, it pushes against the frame and compresses the filter plates.

- The compressive force applied to the filter plates causes the filter cloth to become tightly packed against the slurry, forcing the liquid to pass through while retaining the solids.

- The pressure is maintained for a set period of time to ensure thorough filtration.

- Once the filtration is complete, the hydraulic system is released and the filter plates are opened, allowing the solid cake to be removed and the remaining liquid to be drained.

The hydraulic system can be adjusted to control the amount of pressure applied to the slurry, which can affect the efficiency and effectiveness of the filtration process. The pressure can also be increased or decreased over time to optimize the filtration process for different types of slurry, depending on factors such as the size and shape of the solids, the viscosity of the liquid, and the desired level of filtration.